Explore the crucial role of operational technology in the manufacturing industry, where its significance cannot be overstated. Shed light on the widespread use of outdated systems, which not only jeopardize operations but also expose manufacturers to unforeseen risks. In an era plagued by cyber threats, ponder upon the costly implications of production downtime, leaving us to ponder: what is the true price we pay for neglecting cybersecurity measures?

The Vulnerability of Antiquated Technology

Outdated technology in the manufacturing industry is often not designed to withstand the current landscape of cybersecurity threats. However, these older systems and tools play a vital role in keeping your company running smoothly, making it imperative to address their vulnerability. With the increasing sophistication of cyber threats, it has become evident that neglecting cybersecurity measures can have costly implications for manufacturers.

The manufacturing industry heavily relies on operational technology (OT) to control and monitor critical processes, including production lines, machinery, and supply chain logistics. These OT systems are often outdated and lack the necessary security features to protect against cyber attacks. As a result, they become easy targets for hackers, putting the entire manufacturing process at risk.

Upgrading these antiquated systems is not a simple task. The complexity lies not only in the technical aspect but also in the potential disruptions to operations. These systems are deeply integrated into the manufacturing processes, with custom configurations that have been refined over the years to maximize efficiency. Therefore, any attempt to upgrade or replace them requires careful planning and consideration to avoid substantial downtime and financial losses.

Not only that, but the cost of neglecting cybersecurity measures in the manufacturing industry goes beyond just potential downtime. In the event of a successful cyber attack, manufacturers can face significant financial losses due to halted production, damaged reputation, and potential legal liabilities. The disruption caused by a cyber incident can result in delayed deliveries, missed customer orders, and even contractual breaches, leading to dissatisfied customers and strained business relationships.

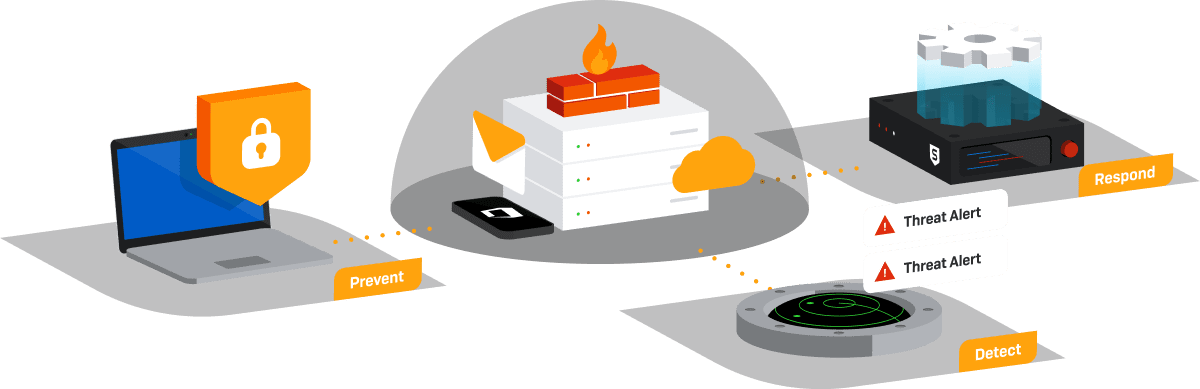

To address these vulnerabilities, manufacturers need to prioritize investing in robust cybersecurity measures that are tailored to their specific operational technology systems. This includes implementing advanced intrusion detection systems, regular patching and updates, network segmentation, and employee training to enhance awareness of cyber threats and best practices for prevention.

The role of operational technology in the manufacturing industry is vital, but its vulnerability to cyber threats cannot be ignored. The complexity of upgrading outdated systems, along with the potential disruptions to operations, poses a significant challenge. However, the cost of neglecting cybersecurity measures is far greater, jeopardizing not only the smooth functioning of the manufacturing process but also the financial stability and reputation of manufacturers. It is crucial for manufacturers to take proactive steps in enhancing their cybersecurity posture to mitigate the risks associated with outdated technology and safeguard their operations in an increasingly hostile digital landscape.

Is your technology stacksafe from threats?

Our Biggest Fear: Downtime

Downtime is a manufacturing company's greatest fear, as it carries significant financial implications.. The cost of production halts goes beyond just the loss of revenue during the downtime itself. It also includes the additional costs associated with missed delivery deadlines, rush orders to fulfill backlogged demand, and potential penalties for contractual breaches, as well as overhead costs such as paying employees who literally can't do their jobs.

When a manufacturing process comes to a halt, the entire supply chain is affected. Suppliers may have to find alternative customers for their products or services, leading to strained relationships and potential loss of future business. Customers, on the other hand, may suffer from delayed deliveries or even have to seek alternative suppliers, resulting in dissatisfaction and the risk of losing loyal customers.

Even the reputation of the manufacturing company is at stake. Customers and partners may lose faith in the company's ability to deliver on time and with consistent quality. This loss of trust can take a long time to rebuild, if ever, and can have a lasting negative impact on the company's bottom line.

In today's fast-paced business environment, where competition is fierce and customer expectations are high, manufacturing companies cannot afford to overlook the importance of minimizing downtime. It is not just about maintaining smooth operations; it is about protecting the overall financial stability and reputation of the company.

Investing in robust cybersecurity measures and upgrading outdated operational technology systems is crucial to mitigate the risks associated with downtime. By implementing advanced intrusion detection systems, regularly patching and updating software, segmenting networks, and providing comprehensive employee training, manufacturers can enhance their cybersecurity posture and reduce the chances of cyber attacks that can lead to costly production halts.

Adapting Modern Solutions

It has become imperative for manufacturing companies to prioritize the modernization of their operational technology (OT) environments. This is where Cyber Advisors comes in as your trusted partner. With our expertise and collaboration with industry-leading partners like Fortinet, we offer advanced network security solutions that provide unparalleled protection against cyber threats.

Our comprehensive suite of services goes beyond just network security. We offer managed IT services to ensure the smooth and efficient functioning of your technology infrastructure. Our team of experts will monitor and manage your systems, promptly addressing any issues or vulnerabilities that may arise.

Additionally, our managed security services offer a holistic approach to safeguarding your operations. We understand that cybersecurity is not a one-time fix, but an ongoing effort. That's why we provide continuous monitoring, threat detection, and incident response to mitigate risks and proactively identify potential threats before they cause damage. We specifically focus on the identification and remediation of problems.

We take a strategic approach to implement robust security measures tailored to your specific operational technology systems. Our vCISO program offers you a Virtual Chief Information Security Officer, who will work closely with your team to assess your current security posture, identify vulnerabilities, and develop a comprehensive cybersecurity strategy. This includes regular patching and updates, network segmentation, employee training, and other best practices to enhance awareness and prevention.

Don't let outdated systems and vulnerabilities jeopardize your operations and put your company at risk. Partner with Cyber Advisors to securely modernize your operational technology and ensure the safety and integrity of your manufacturing processes. Together, we can navigate the complexities of cybersecurity and empower your business to thrive in an increasingly hostile digital landscape.

Fortinet for OT

Fortinet, one of our biggest partners, is a leading provider of cybersecurity solutions specifically designed for the operational technology (OT) landscape. With their extensive knowledge and expertise in securing OT systems, they offer a comprehensive range of cutting-edge technologies to protect manufacturers from cyber threats.

Fortinet understands the unique challenges faced by manufacturers in securing their OT systems. They recognize that these systems are often outdated and lack the necessary security features to defend against sophisticated cyber attacks. That's why Fortinet has developed top-of-the-line endpoint protection, extended detection, and response capabilities, specifically tailored to the needs of the manufacturing industry.

When a threat is detected, Fortinet's robust infrastructure swiftly responds, ensuring minimal downtime for manufacturers. Their advanced technologies and proactive approach allow for rapid threat identification and remediation, preventing potential disruptions to operations. With Fortinet as a partner, manufacturers can have peace of mind knowing that their OT systems are protected by state-of-the-art security solutions.

By partnering with Fortinet, manufacturers can benefit from their deep understanding of the manufacturing industry and their commitment to providing tailored cybersecurity solutions. With Fortinet's expertise, manufacturers can enhance their cybersecurity posture, safeguard their operations, and mitigate the risks associated with outdated technology.

In conclusion, Fortinet's partnership with Cyber Advisors brings unparalleled expertise and knowledge to the table, specifically addressing the unique challenges faced by manufacturers in securing their OT systems. With Fortinet's top-of-the-line endpoint protection, extended detection, and response capabilities, manufacturers can confidently navigate the complexities of the digital landscape and ensure the safety and integrity of their manufacturing processes. Together, Cyber Advisors and Fortinet empower manufacturers to thrive in an increasingly hostile cybersecurity landscape.

Cyber Advisors - The Partner you Need

At Cyber Advisors, we possess the expertise and strategic partnerships to address all your OT requirements. From vCISO services to help desk support and managed IT solutions, we offer a comprehensive range of services to ensure the uninterrupted operation of your business. Rest assured, we have everything you need to keep your operations running smoothly. If you would like more information, please don't hesitate to get in touch with us.

Ask a Pro